What is 3D laser scanning for Industrial Plants?

In existing facilities or industrial plants, everything has a potential to change. 3D laser scanning for industrial plants, leads every aspect of engineering projects in plants and facilities. A single scan can provide an incredible amount of information about existing conditions of your industrial plant.

Solvotek International specializes in 3D laser scanning for industrial plants and facilities and modelling services with offices based in New York. We deliver 3D laser scan data or 3D models in multiple formats to meet your needs. If you want to know more call us!

In today’s industrial environment, it is becoming increasingly important to have accurate and up-to-date information about your plant and facility assets. This is where 3D plant models come in. Using intelligent PDMS/E3D models, oil and gas plant 3D as-built scans and factory 3D scans, you can create a digital twin of your plant that provides as-built data for revamp projects, tank inspections, deformation analysis and coke drum inspections. This not only helps with visual asset management, but also allows for more efficient planning and maintenance of your sites. With accurate as-built data, you can make informed decisions about the future of your facility, reduce downtime and increase productivity. So if you are looking for ways to optimize your plant’s performance, consider making an investment in 3D plant models and digital twin technology.

Types of 3D laser scanners

Terrestrial 3D laser scanners are advanced devices that use a motorized system to project laser beams onto an object. The scanner head provides a full 360° scan of the area by rotating the laser head horizontally and vertically. The scanner calculates the coordinates of the object using methods that vary depending on the type of scanner. The energy returned by the laser beam determines the intensity of each point on the object.

The result is a 360° point cloud of millions of points with x, y and z coordinates and intensity values. Some scanner models also have an integrated camera that captures r, g, b data on the measured point. If images are acquired during scanning, the resulting point cloud is a colored 3D point cloud containing x, y, z coordinates, intensity information and r, g, b color information. These structured point clouds are so named because the position of the scanner relative to the point cloud is known.

On the other hand, handheld lidars and mobile scanners capture laser scan data on the go. They use sensors such as GPS, IMU and odometers or SLAM algorithms to resolve the coordinates of each point. SLAM-based scanners are gaining popularity due to their ability to cover larger areas in shorter scan time with an accuracy in the centimeter range. Such scanners are ideal for covering large confined areas and are available in both handheld and vehicle-based models.

Aerial or vehicle-based mobile mapping platforms scan the environment using fixed laser arrays and use GPS, IMU and odometer sensors to calculate location information. Due to their dependence on GPS information, these platforms are not suitable for indoor scanning projects, but are designed to cover large open areas.

What are the benefits of 3D laser scanning for Industrial Plants?

Change orders and rework can be expensive. During construction of new facilities or revamp, renovation project as-built data plays crucial role for engineers. As-built of industrial facilities can be realized much more efficiently and accurately with the help of 3D laser scanning technology. This approach provides benefits like accuracy, quick turn-around time, efficient collaboration among project teams and complete data with non-intrusive surveying methods. Collecting data in hard to reach areas is much easier with 3D laser scanners!

Many of the advantages to use as-built laser scan data can directly be seen in your facility renovations, revamp projects, expansion projects and digital twin. Having a 3D laser scanning service provides more accuracy, more speed, lower costs and better coordination for the teams and managers working on the project. Your project is in safe hands from the kick off until the end of your project.

3d laser scanning in industrial plants and facilities are used for :

- 3D Plant Models

- Intelligent PDMS / E3D models

- Oil & Gas Plant 3D as-built scans

- Factory 3D scans

- Digital Twin

- As-built Data for Revamp Projects

- Tank Inspections

- Deformation Analysis

- Coke Drum Inspections

- Visual Asset Managements

Solvotek Deliverables

- Pointcloud Data

- 2D CAD Drawings

- 3D Non Intelligent Models

- 3D BIM Models

- 3D Mesh

- Orthophotos

- Plan View Drawings

- Elevation Drawings

- Facade View Drawings

- Architectural Section Drawing

Our 3D laser scanning services for other sectors

We provide 3D laser scanning services all across AEC sector. We are working with contractors, subcontractors, freelancers, architecture design firms, industrial plants, energy companies, mechanical engineers, BIM managers, marine engineers…etc.

Architectural 3D laser scanning

At Solvotek International, we use high-precision 3D laser scanners to complete the most precise work in architectural services. Our goal in architectural 3D laser scanning is to provide architects with highly accurate and complete 3D point cloud data, allowing them to design and draw more accurately, work remotely and visualize projects easily. In architectural projects for accurate existing conditions surveys, we examine the project details, places that need extra attention before the work and setup our 3d laser scanners to the optimum setup positions in the most effective way.

Our services includes office and residential renovations, site plans, sections, layout plans, reflected ceiling plans, elevations, facade drawings, scan to BIM, and door, window, column, and casework detail drafting.

- Site Plans

- Sections

- Layouts / Floorplans

- Reflected Ceiling Plans

- Sections

- Elevations

- Facade Drawings

- Scan to BIM

3D laser scanning for Construction

The biggest challenge in construction is the coordination among different subcontractors. The collaboration on BIM is a good fit to solve this issue on the design phase. When it comes to the construction phase, the same collaboration should be done. 3D laser scanning helps to control and verify the construction. It can also help to see clashes according to the as built of the environment. Either to get measurements for floor flatness, or to see the progress of the construction, 3D laser scanning helps in various stages of the construction. Main uses of 3D laser scanning is to get existing conditions in construction. It can also be used for quality assurance, documentation of construction progress, as well as providing a permanent as-built record. 3D laser scanning is a valuable equipment in construction services and has many benefits.

- 3D BIM verification

- Progress Reports

- Floor Flatness Analysis

- Scan to BIM

- Asbuilt Data for Construction

- Bridge and Tunnel Surveys

- Deformation Analysis

Marine 3D laser scanning

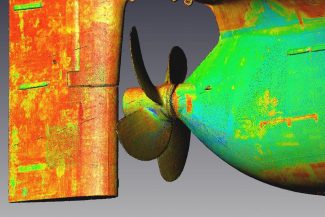

Our 3D laser scanning solutions for the marine industry are designed to meet the unique needs of each project. We offer a variety of services, such as 3D laser scanning for ballast water treatment, tank calibration of ships, reverse engineering of vessels that lack proper as-built documentation, hull and propeller modeling, and existing conditions surveys for yachts. Our 3D scanning process is an efficient technology that reduces the need for manual labor in measuring physical objects or environments. Our 3D laser scanning services for marine allow for precision in design documentation and help save time and money in shipbuilding projects. 3D laser scanning solutions are perfect for tank models, hull and deck models, propeller models, reverse engineering, tank calibrations, and ballast water treatment projects as well as documentation of the shipyards.

- 3D Tank Models

- Hull Models

- Propeller Models

- Reverse Engineering

- Ship Interior As built Models

- Tank Calibrations

- Ballast Water Treatment Projects