Our approach to vessel tank calibrations

Tanker ships’ tanks gets calibrated regularly to define the exact volume of the tank. The liquid put in the tanks is measured and priced by the calibration certificates. It is so important to get the calibration as accurate as possible. We do 3D laser scanning for tank calibration purposes, We create highly precise 3D tank models and volume calculations to be used in calibration certification.

Our approach for vessel tank calibrations starts with highly accurate tank scanning. Using high end terrestrial 3D laser scanners, we do scan each tank from multiple scan locations using targets and register them with high accuracy. Even the slightest errors in the registration can yield to large volumetric discrepancies in the final calibration. Since some of the tanks are already in use, we need the tanks to be cleaned and checked for any gas precipitation before our field crew goes in with appropriate PPE.

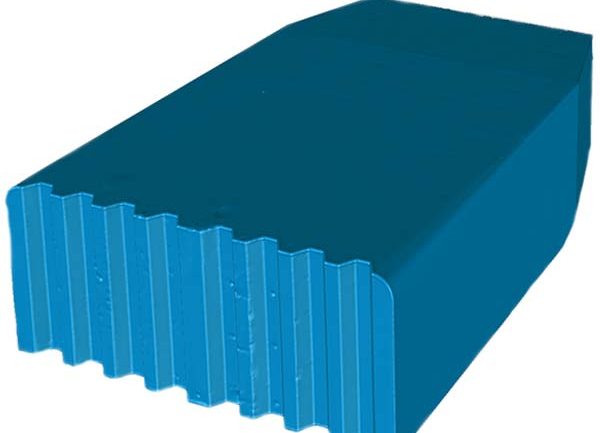

All the 3D laser scan files are registered together using target based bundle adjustment method to achieve the highest accuracy possible. The registered scan files than converted to water tight mesh models that are free of any installations inside the tanks. Final volumetric calculations and the tank calibration tables are created.