The role of 3D Laser Scanning in Marine Services

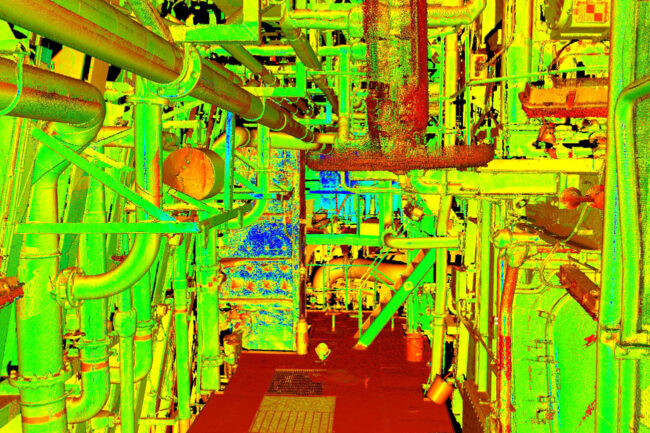

In the marine industry, accurate information about the current condition of ships and other marine structures is crucial for successful engineering projects. 3D laser scanning is revolutionizing the marine industry by allowing marine service providers to obtain precise real data of marine environments, ships, and structures with remarkable accuracy.

At Solvotek International, we specialize in 3D laser scanning for marine services and provide scanning, tank calibration and CAD modeling services to clients worldwide. Our offices are located in New York and we deliver 3D laser scanning data or 3D models in multiple formats to meet your needs. Our team uses a variety of 3D laser scanners to capture million of points to create real data pointcloud of the existing conditions.

When you need a reliable 3D laser scanning service for your ship or vessel inspections, hull scanning, ballast water treatment surveys, bow, aft, propeller reverse engineering or existing condition surveys of piers, jetties, look no further! Our expert team is equipped with the latest technology and knowledge to provide you with highly accurate data. Contact us today to learn more about our top-notch marine scanning services!

Solvotek International provides a comprehensive 3D laser scanning service to support vessel owners and yards in staying ahead of the market by enabling efficient project planning, refit design. Our strategic collaboration with naval companies and field specialists allows us to deliver high-quality services tailored to meet the specific needs of shipping companies. Count on us to provide 3D laser scanning services that help streamline your marine operations.

You may have many questions about how a ship can be scanned to fit our needs? Laser scanning technology offers a quick, easy, and highly accurate 3D data for tank calibrations and retrofitting projects. Laser scans can often be performed in a single day, and even during smaller operations like BWTS or scrubbing water system retrofits, they can be done while the crew is on board, saving valuable time. The use of scanning not only helps shorten the time of service but also enables shipyards and shipowners to plan and design refits, renovation and begin work as soon as the vessel reaches the repair dock.

Incorporating laser surveying into a vessel’s lifecycle management can have a significant impact, especially for smaller fleets, where a single vessel being out of service can greatly affect the whole operation. This is particularly relevant for yards involved in maintenance and repair contracts for naval and naval support ships. 3D laser scans can help create intelligent and accurate 3D models that are useful for refits and conversions, making them more efficient and cost-effective. With the availability of detailed and accurate 3D surveys from laser scan data, both shipowners and shipyards can benefit from faster and more streamlined operations.

3D laser scanning technology is being increasingly adopted by marine service providers to improve their operations and deliver better results. Let’s explore together the benefits and applications of 3D laser scanning for marine services with Solvotek Internationals professional team.

The Benefits of 3D Laser Scanning for Marine Structures and Environments

There are multiple advantages of 3D laser scanning in marine services. Here are some of the main benefits of having a real data:

Accurate and detailed data: This allows marine service providers to gain a comprehensive understanding of vessel conditions, including engine rooms, mechanical rooms, tanks, deck and other parts of the vessel. With the use of 3D laser scanning, marine service providers can obtain accurate and reliable data for improved decision-making and more effective maintenance and repair operations.

Time and cost savings: Compared to traditional surveying methods, 3D laser scanning can save significant time and cost in data acquisition, processing, and analysis. This technology eliminates the need for manual measurements, reduces site time, and minimizes downtime of marine structures.

Improved safety: 3D laser scanning reduces the need for working in hazardous and challenging environments, such as confined spaces. It also minimizes the risks of human error, improving safety and reducing accidents.

Better decision-making: The data captured through 3D laser scanners can provide marine service providers with a better understanding of the conditions of marine structures and environments, enabling them to make informed decisions for maintenance, repairs, renovations and upgrades.

The marine industry is increasingly using 3D laser scanners, a tool that provides a wide range of advantages to organizations. High-resolution scanners’ capability enables the capturing of data in different environments which allows for quick and easy inspection of structures such as ships, tanks, pumps, docks, hulls, propellers, asbuilt documentations ,engine room, water treatment systems without the need for expensive and time-consuming alternatives.

A Beginner’s Guide to Using 3D Laser Scanners in Marine Services

Here’s a beginner’s guide to using 3D laser scanners in marine services:

- Understand the technology: 3D laser scanners use lasers to bounce off surfaces and create a digital point cloud, which is a collection of millions of individual points that together create a 3D representation of the object being scanned. These point clouds can then be used to create highly detailed digital models or maps.

- Choose the right scanner: There are many different types of 3D laser scanners available, each with their own strengths and weaknesses. When choosing a scanner for marine services, it’s important to consider factors such as range, accuracy, noise, portability, and durability.

- Plan the scanning process: Before scanning, it’s important to plan out the process to ensure that all necessary areas are covered and that the data collected is accurate and complete. This may involve creating a scanning strategy or developing a 3D modeling plan.

- Conduct the scanning: Once the planning is complete, the actual scanning can begin. This typically involves positioning the scanner at different locations around the asset being scanned, and capturing multiple scans from different angles to create a complete 3D model.

- Process the data: After the scanning is complete, the point cloud data must be processed to create a usable 3D model. This may involve cleaning up the data, merging multiple scans together, and creating a final model or map.

- Use the data: Once the 3D model is complete, it can be used for a variety of purposes, such as maintenance planning, damage assessment, or design and engineering work.

3d laser scanning in marine are used for :

- Tank calibrations

- Hull and deck scanning

- Ballast water treatment systems piping design

- Scrubber system retrofit projects

- Propeller scanning and reverse engineering

- Interior design

- Engine Room as-built survey

- Mechanical room as-built survey

- Offshore platform existing conditions surveys

Solvotek Deliverables

- 3D Pointcloud Data

- 2D CAD Drawings

- Isometrics

- 3D Non Intelligent Models

- 3D Intelligent Models

- CAD models

- Tank calibration tables

- Deformation Analysis reports

Our 3D laser scanning services for other sectors

We provide 3D laser scanning services all across AEC sector. We are working with contractors, subcontractors, freelancers, architecture design firms, industrial plants, energy companies, mechanical engineers, BIM managers, marine engineers…etc.

Architectural 3D laser scanning

Our 3D laser scanning services at Solvotek International are specifically designed for architectural projects that require the highest precision. Our skilled professionals use cutting-edge 3D laser scanners to capture highly accurate and detailed data of architectural environments, providing architects with complete 3D point cloud data for designing and drawing with greater accuracy.

For accurate existing conditions surveys, we examine project details and areas that require extra attention before setting up our 3D laser scanners in the most effective positions. Our architectural services include office and residential renovations, site plans, sections, layout plans, reflected ceiling plans, elevations, facade drawings, scan to BIM, and detailed drafting of doors, windows, columns, and casework. With our advanced 3D laser scanning technology and expertise, architects can work remotely and easily visualize projects for streamlined and effective operations.

- Site Plans

- Sections

- Layouts / Floorplans

- Reflected Ceiling Plans

- Sections

- Elevations

- Facade Drawings

- Scan to BIM

3D laser scanning for Construction

3D laser scanning technology is a powerful tool that can aid in controlling and verifying construction, detecting clashes based on the as-built environment, measuring floor flatness, and monitoring construction progress. Obtaining existing conditions through 3D laser scanning is one of the primary uses of this technology in construction services. It can also serve as a quality assurance tool, help with documentation of construction progress, and provide a permanent as-built record.

Overall, 3D laser scanning is an invaluable equipment for construction services, offering numerous benefits such as increased accuracy, improved efficiency, and streamlined collaboration among different subcontractors.

- 3D BIM verification

- Progress Reports

- Floor Flatness Analysis

- Scan to BIM

- Asbuilt Data for Construction

- Bridge and Tunnel Surveys

- Deformation Analysis

Industrial 3D laser scanning

In industrial projects, 3D laser scanning is a valuable technique for creating precise digital representations of plants and facilities. With applications ranging from revamp projects to reverse engineering, 3D modelling, inspection, and maintenance, 3D laser scanners are a must-have tool for industrial projects. Accurate and efficient data collection through 3D laser scanning can help improve productivity, reduce rework costs and clashes, and ensure better coordination among teams and managers. Choosing a reliable 3D laser scanning service can provide faster turnaround times, improved accuracy, lower costs, and a smoother project execution from start to finish.

- 3D Tank Models

- Hull Models

- Propeller Models

- Reverse Engineering

- Ship Interior As built Models

- Tank Calibrations

- Ballast Water Treatment Projects