The typical approach when performing ship inspections is to bring the designers and engineers to the ship, where they record measurements of existing systems and areas using a tape measure. Laser scanning for the marine industry is of great importance. These measurements are then used in the development of scope and construction documentation. However, the uncertainty of measurements requires the inclusion of allowances to account for inconsistencies between measurements and reality. These allowances can be expensive, or the space may be considered too small when there is enough space. Therefore, it can also prevent the installation of new equipment in a particular location.

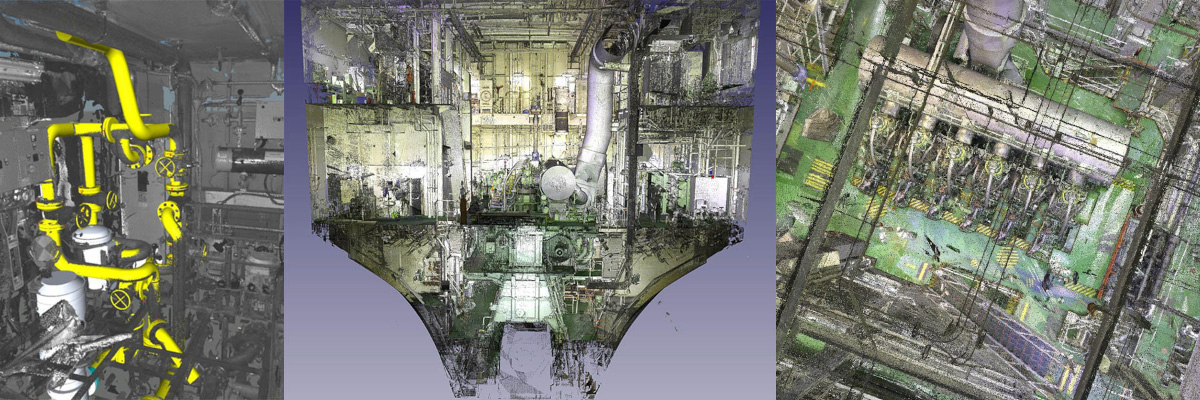

Laser scanning for the marine industry involves scanning ship areas with a 3D laser scanner to create a detailed and accurate 3D point cloud model. Today’s high-speed laser scanners are well suited for this purpose, as they can take tens of millions of measurements in just a few minutes. Scans are made from various locations to provide adequate coverage around the equipment. Scans are then saved together to bring them all to the same coordinate system.

So, what are the usages of 3D laser scanning in the marine industry? You can continue reading our article to learn about the subject.

Ballast Water Treatment Surveys

All ships underway must manage their ballast water and sediments to a certain standard. Ballast water treatment surveys help shipowners install BWT on board with high precision.

3D laser scanning for the marine industry enables the conditions that the boat or ship should have before the Ballast Water Treatment System. Scanning also provides accurate measurements and detail of existing pipes and structures.

3D Tank Models and Tank Calibration

Tanker ships’ tanks are calibrated to determine the exact tank volume. The liquid put into the tanks is measured and priced with calibration certificates. There are 3D laser scanning services for tank calibration. At Solvotek, we create highly accurate 3D tank models and volume calculations for use in calibration certification.

Vessel Retrofits

The use of 3D Laser Scanning, although available, is not considered a mainstream application in ship repair and retrofit operations. By using 3D laser scanning, the vessel (or any part of it) can be modeled according to requirements accurately in a timely manner, which will speed up the retrofitting process drastically.

Reverse Engineering

Reverse engineering is the process of reproducing a part by extracting surfaces or sketches from a scanned point cloud or mesh to create a CAD model of the part. The product reflects how the piece was originally designed.

Reverse engineering is becoming a more popular method of creating a 3D model of a part that does not have previous CAD files. 3D scanning is an ideal process for reverse engineering. The collected data is treated as a point cloud, which is a three-dimensional image of the scanned object. It also allows us to create virtual assemblies that allow us to detect overlap and check the fit of parts.

As Solvotek, we are here to assist architects, engineers, BIM managers, facility managers, naval architects, and plant managers in scanning and documenting the built conditions of project sites. You can contact us for more information.